Ark marine Ltd. (https://www.ark-marine.com) has developed a carriage and launching device for yachts. The dinghy derrick is a device attached to the rear of a yacht which can carry and launch a dinghy (small boat) with ease. They asked me to write software to help with their production process of a crucial part of the dinghy derrick.

What

A dinghy derrick must be mounted onto the yacht. This is not straightforward because yachts are curved, and each yacht is different. To make sure the dinghy derrick arms sit parallel, they must be mounted on a hinged bracket. The bracket must be securely fixed to any 3D curvature of the hull. A 3D shaped rubber block is created with the same curvature as the yacht. This rubber block is custom made and based on measurements of the yacht.

How

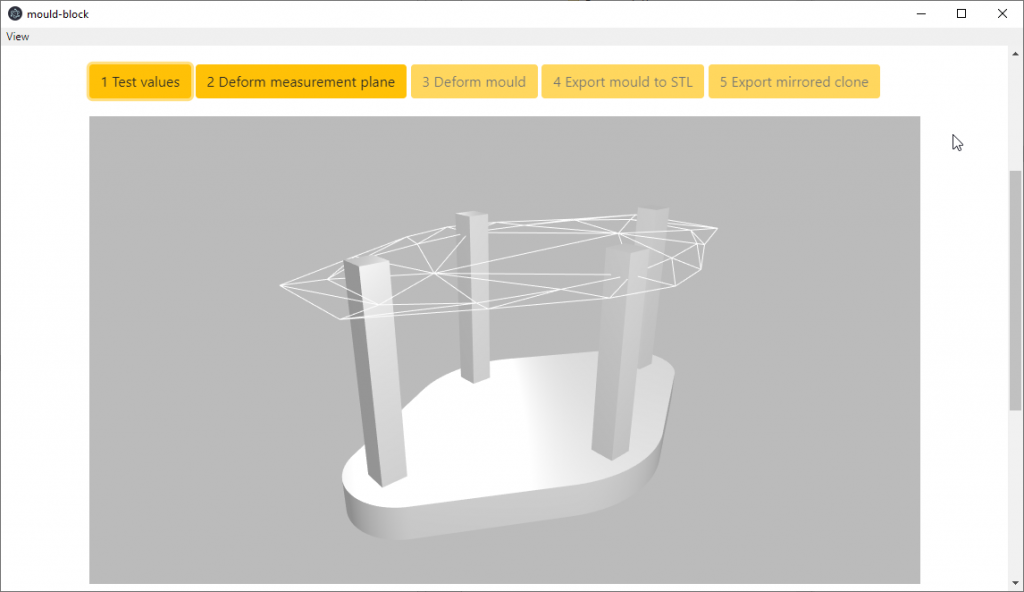

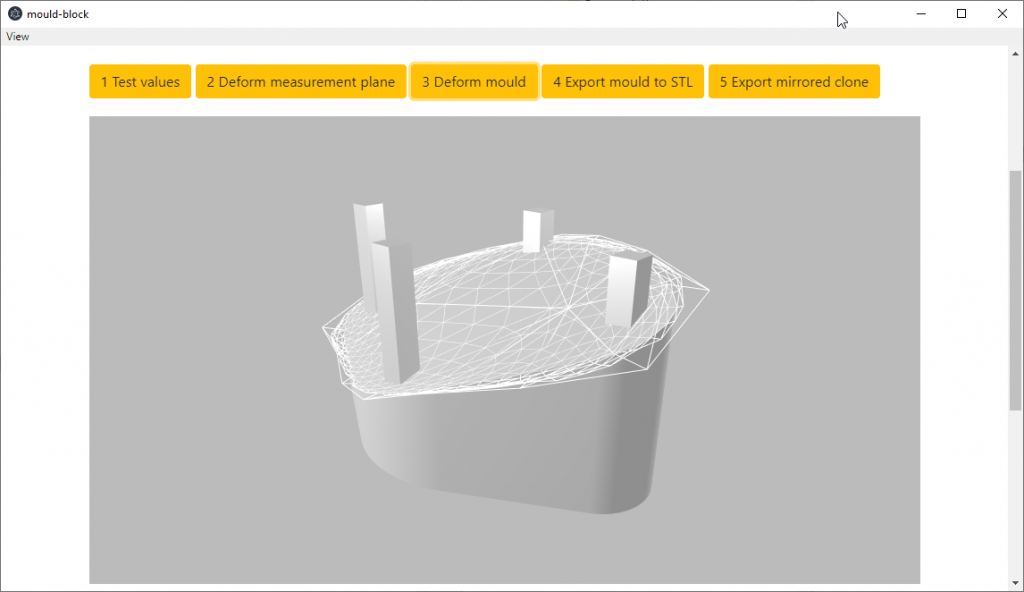

A plastic block on a suction clamp allows the user to take a standard set of depth measurements to the hull surface. After the measurements are taken, they’re fed into the software. I’ve built a tool which shows a blank molded block in 3D. The measurements taken from the yacht deform the 3D model. Finally, a file is generated which can be sent to the production facility to create the rubber block. The block is molded in one mold, all in the same section but with differing curved faces.

I’ve built the tool with three.js for realtime deformations. It’s embedded in an electron app which makes it very portable and independent from a specific browser. The app doesn’t need an internet connection.

Benefits

This is a lightweight, standalone tool. It’s something you can use on your laptop while you’re on the road. It’s easy to use and doesn’t require an engineering background. This makes the process of manufacturing custom molded plates a lot faster and viable.

Testimonial

The biggest challenge with the dinghy derrick is how it’s bolted onto a yacht. We measure the complex 3D curved surface of a yacht. This helps with creating a 3D shaped rubber plate. This is the interface between the yacht and dinghy derrick and makes sure the two arms of the dinghy derrick stay exactly parallel. But we couldn’t find a simple software product to take these measurements and create manufacturing files. It didn’t exist. I turned to Klaas Nienhuis who, with great cooperation and thought, invented it. The idea will have hundreds of other applications. It is easy to work with, reliable and effective.

The biggest challenge with the dinghy derrick is how it’s bolted onto a yacht. We measure the complex 3D curved surface of a yacht. This helps with creating a 3D shaped rubber plate. This is the interface between the yacht and dinghy derrick and makes sure the two arms of the dinghy derrick stay exactly parallel. But we couldn’t find a simple software product to take these measurements and create manufacturing files. It didn’t exist. I turned to Klaas Nienhuis who, with great cooperation and thought, invented it. The idea will have hundreds of other applications. It is easy to work with, reliable and effective.

Mike Arkell, inventor of the Dinghy Derrick and CEO at Ark Marine Ltd.